1 / 3

1 / 3Autonomous flow of goods with pick and place robot

Hardware Price:

Pick performance

400

Packages per hour

Payload

500

Gramm

Operation

24/7

hours

Automating Pharmacy Storage with Apostore Pick-and-Place Robot:

Efficiency and Safety

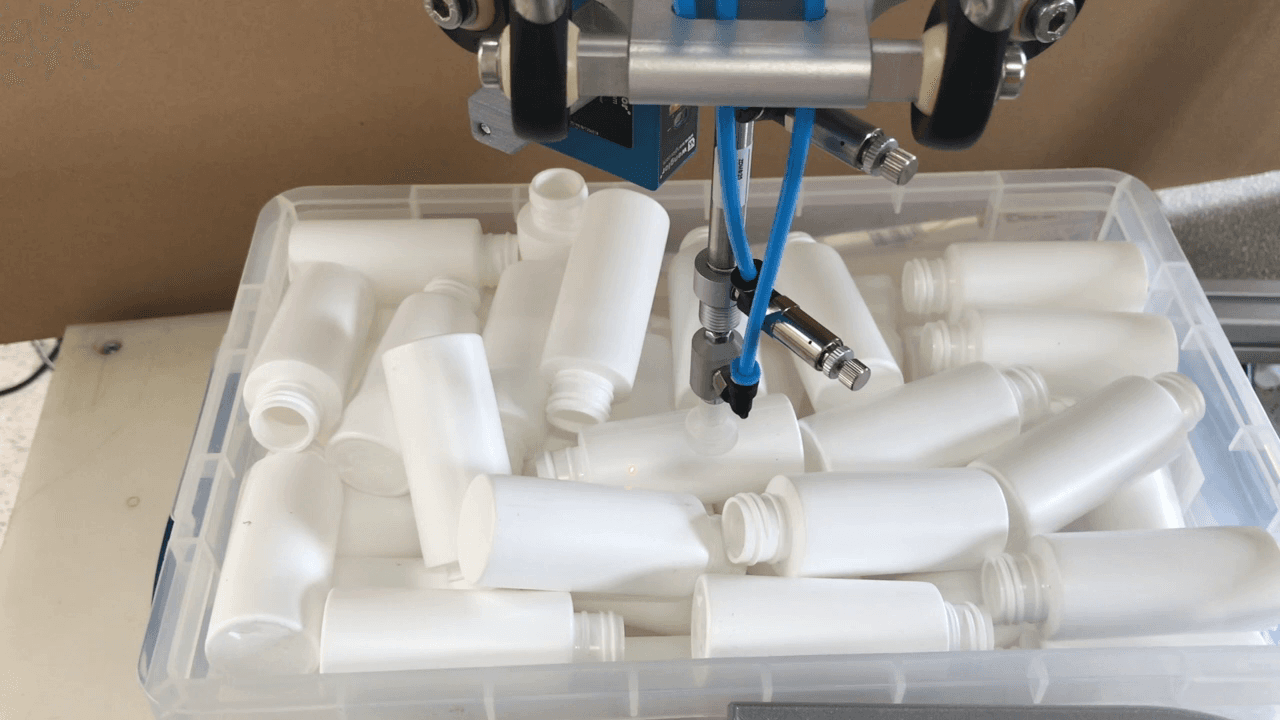

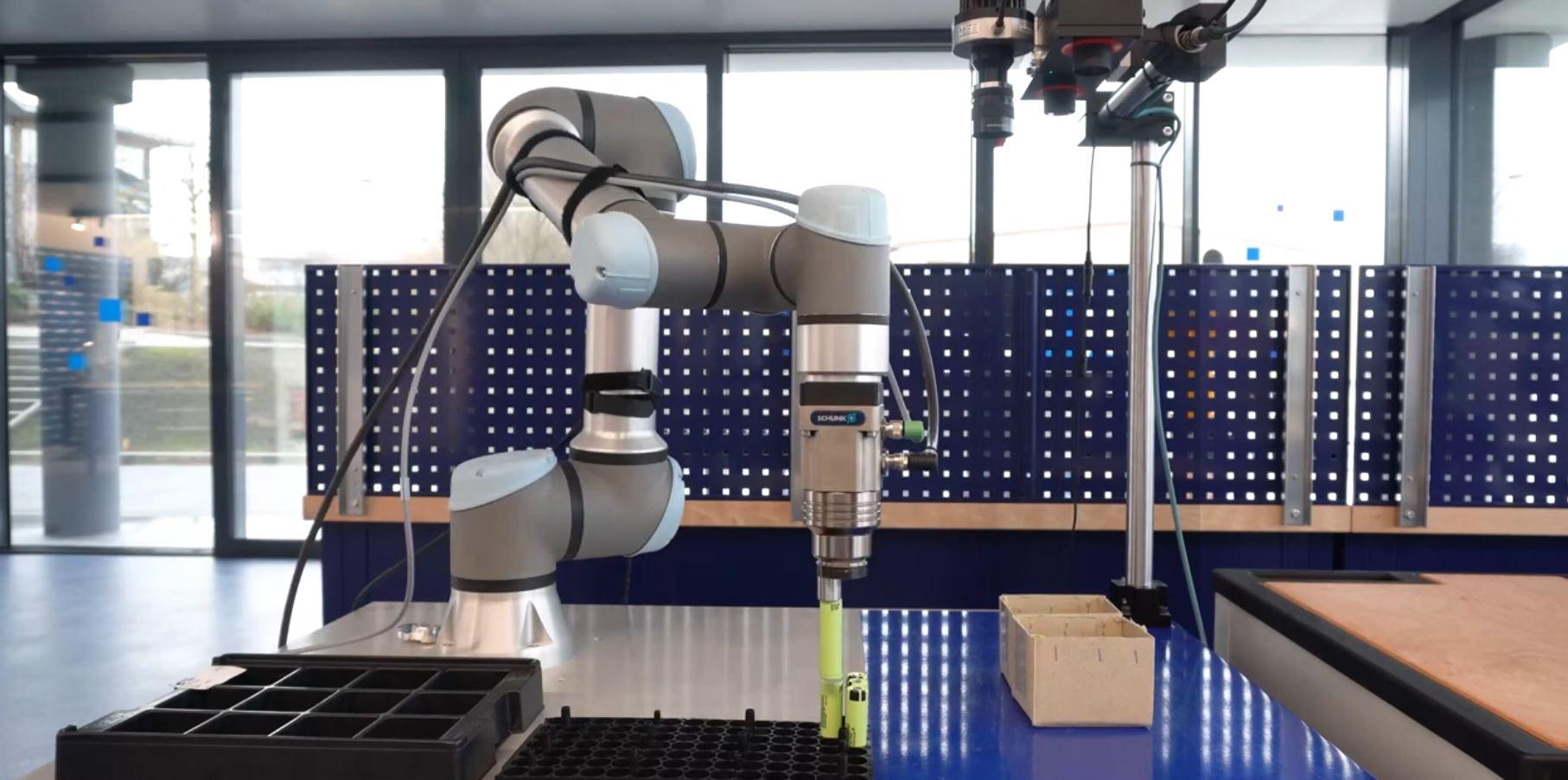

Ensuring quick access to medicines is critical for pharmacy operations. Apostore’s pick-and-place robot solution automates the storage of medications, integrating seamlessly with delivery note management and merchandise systems. Operating 24/7, this system sorts bulk medication autonomously, reducing errors and freeing pharmacy staff to focus on customer service. Equipped with a robolink robot arm, 3D Smart Sensor Vision System, and Beckhoff controller, it guarantees precision storage and safety.

What is the Application?

The robot automates sorting and storage of medicine packs, handling tasks such as scanning and placing individual items on a conveyor belt to prevent mix-ups.

What are the Advantages of the Solution?

High Efficiency: Processes over 400 packs per hour, ensuring rapid inventory sorting.

Improved Accuracy: Automated scanning eliminates errors and guarantees safety.

Continuous Operation: Functions 24/7, maximizing productivity in busy pharmacies.

What are the Advantages of the Robot?

The robolink robot arm provides reliable and adaptable automation:

Precision Handling: Efficiently places packages weighing up to 500g.

Easy Integration: Functions with minimal requirements—6 bar compressed air and 230V power.

Scalability: Automatic bin changers eliminate manual intervention and enhance throughput.

Revolutionizing Medicine Storage with Automation

Apostore’s automated solution combines reliability, speed, and safety to optimize pharmacy operations. By automating storage processes, pharmacies can improve workflow efficiency, reduce errors, and offer faster service to customers—a win-win for modern health supply chains.

5 Components