1 / 3

1 / 3Gantry robot for automated part handling in injection molding machines from BOY

Hardware Price:

DOF

3

Max. payload

5

kg

Runtime

24h

Automated Parts Handling with BOY 35 E and igus Low Cost Automation

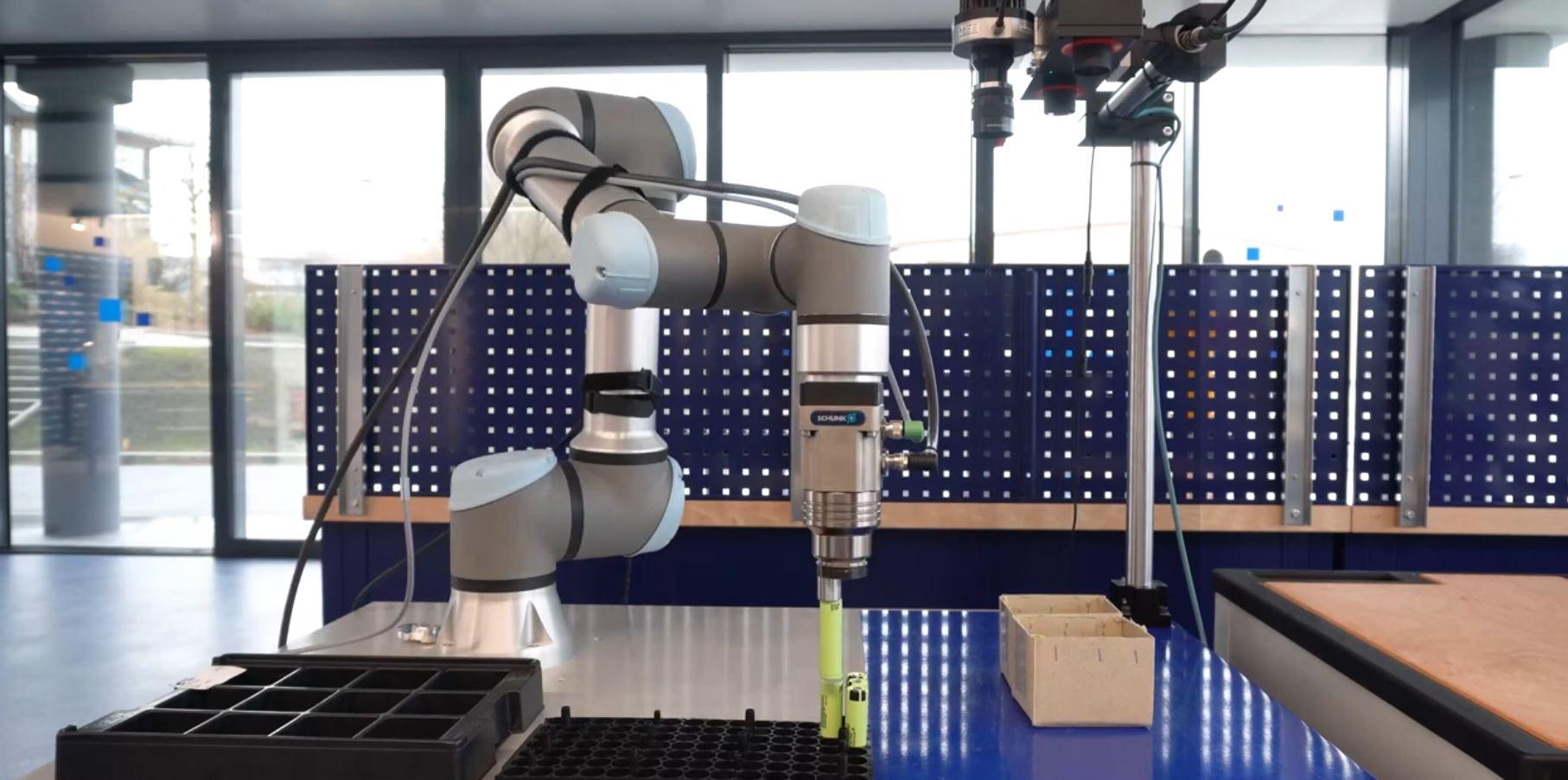

Dr. BOY GmbH & Co. KG, renowned for compact injection molding machines, has partnered with igus Low Cost Automation to optimize parts handling in its BOY 35 E series. This integration combines precision manufacturing with flexible automation, providing customers a faster return on investment. The BOY 35 E is ideal for producing precision parts in tight tolerance ranges, and its compact design makes it perfectly suited for efficient operations.

What is the Application?

The system automates pick-and-place handling for injection-molded parts. Using igus’s linear portal, customers can implement maintenance-free automation for various tasks, replacing less flexible pneumatic pickers.

What are the Advantages of the Solution?

Cost-Efficiency: igus portals are affordable and lower operational costs.

Flexible Configuration: Online programming tools allow assembly personalization.

Maintenance-Free: Reduces downtime and servicing requirements for continuous operations.

What are the Advantages of the Robot?

The igus Low Cost Automation solution delivers:

Ease of Implementation: Quick setup and configuration via an intuitive platform.

Scalability: Allows adaptation to diverse tasks and production needs.

Reliability: Durable components ensure consistent and precise handling.

Streamlining Injection Molding with Flexible Automation

The BOY 35 E coupled with igus automation portals redefines parts handling efficiency. Introduced at Fakuma 2023, this innovative solution attracted great interest due to its flexibility and cost-effectiveness. By enabling automated, precise handling, it enhances productivity, reduces costs, and positions itself as a key tool for modern injection molding processes.

4 Components