1 / 3

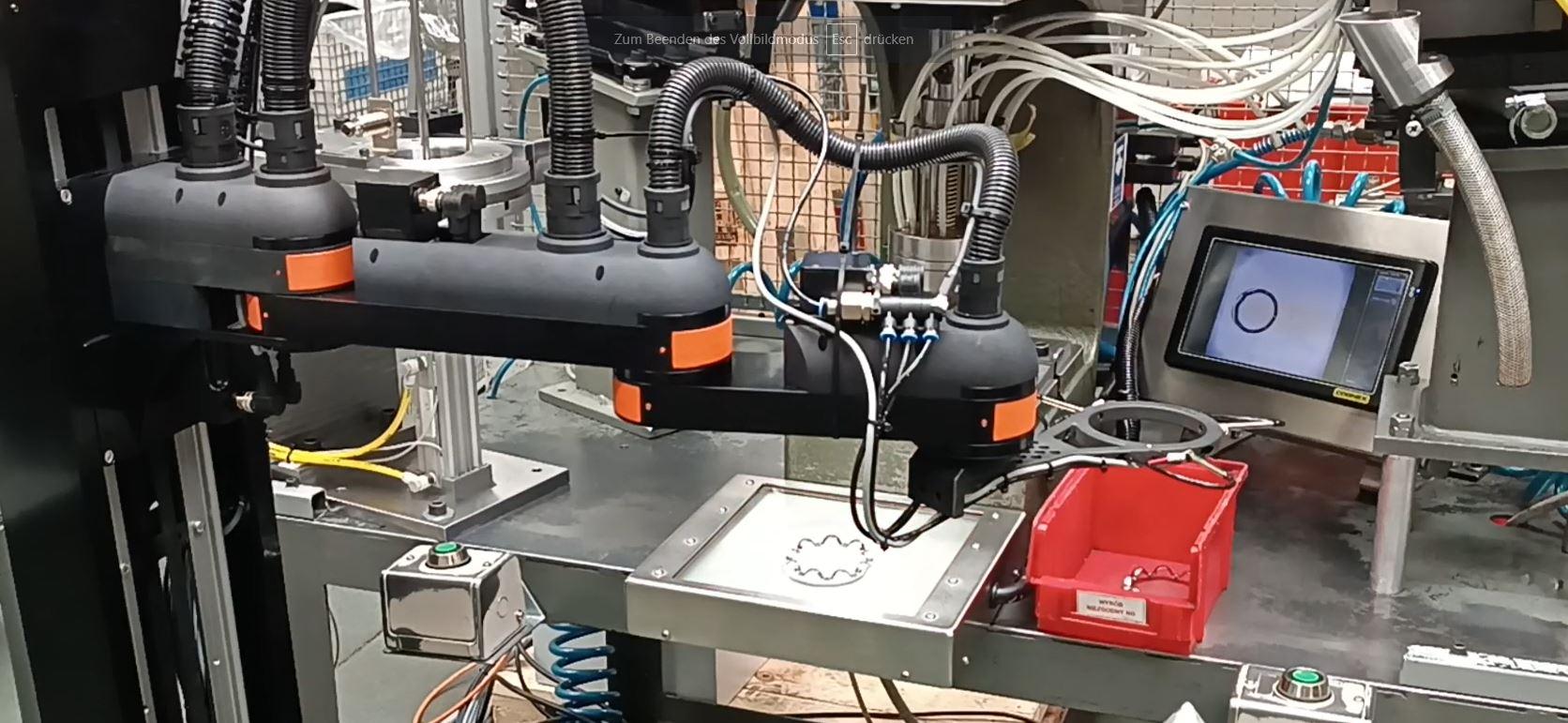

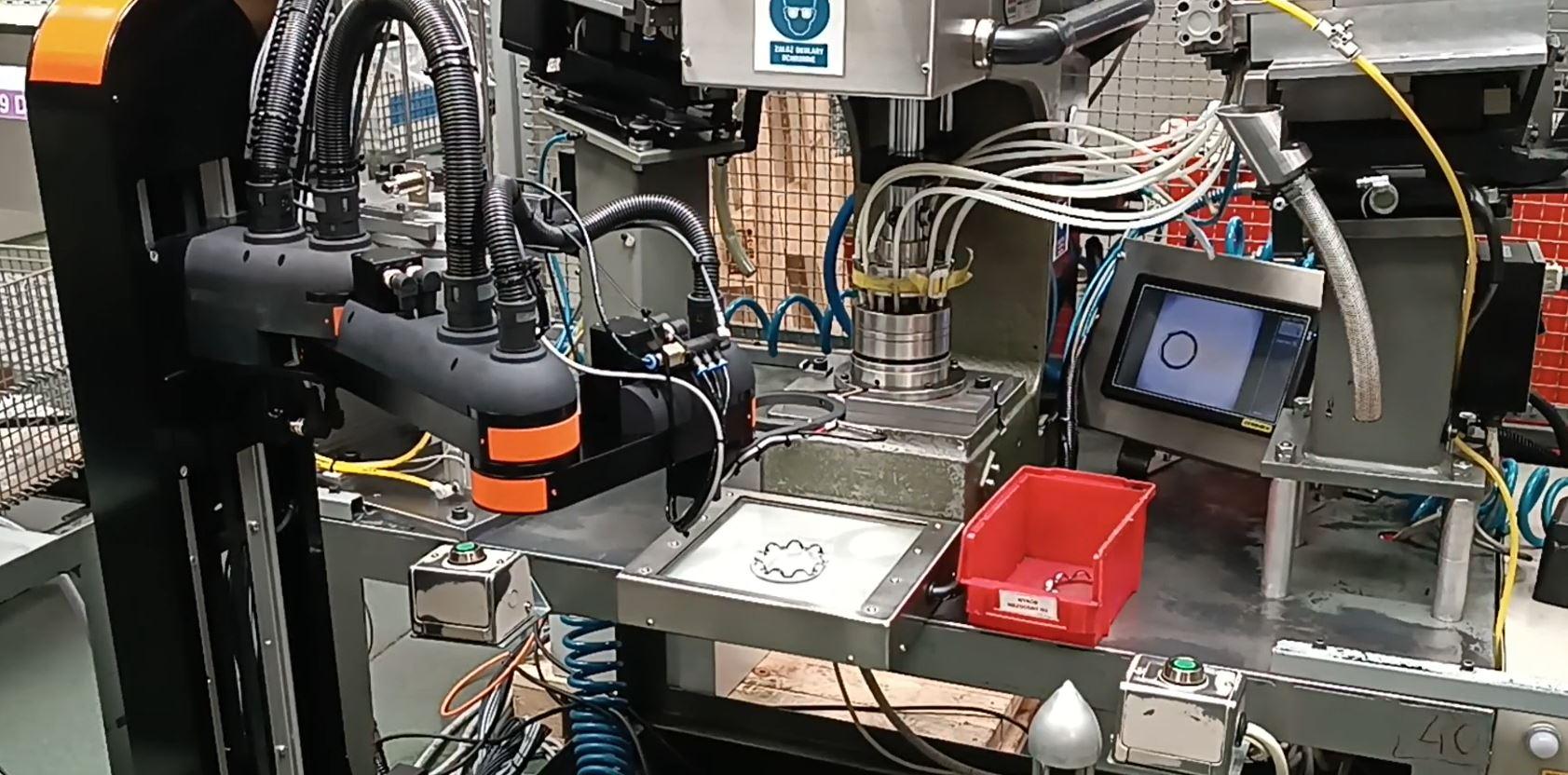

1 / 3Automated ring insert and quality control with SCARA robot

Hardware Price:

ROI

24

months

DOF

4

Max. payload

2

kg

Optimizing Ring Production with SCARA Robot: Precision and Quality Assurance

Automating ring production demands efficiency and consistency to meet high-quality standards. A SCARA robot has been implemented to execute ring insertion, shaping, and quality control with remarkable precision. This automated solution boosts efficiency while ensuring consistent product quality by sorting defective rings into a red box and placing good rings over a bar based on photographic analysis.

What is the Application?

The system automates the insertion and quality control of rings. The SCARA robot shapes the rings, captures their image for inspection, and sorts them based on the results, creating a streamlined and error-free production process.

What are the Advantages of the Solution?

Improved Efficiency: Reduces production time via automation.

Enhanced Quality Control: Consistent inspection minimizes product defects.

Reduced Labor Dependence: Automation decreases reliance on manual effort, lowering costs.

What are the Advantages of the Robot?

The SCARA robot is tailored for precision and reliability:

High Accuracy: Guarantees precise shaping and sorting tasks.

Fast Processing: Speeds up operations to improve throughput.

Compact Design: Fits seamlessly into diverse production environments.

Automation Driving Quality and Efficiency

This SCARA-based ring production system demonstrates how automation optimizes workflows and ensures high standards. By enhancing speed, precision, and reliability, it allows businesses to achieve consistent results while reducing costs, paving the way for smarter production methods.

3 Components