1 / 5

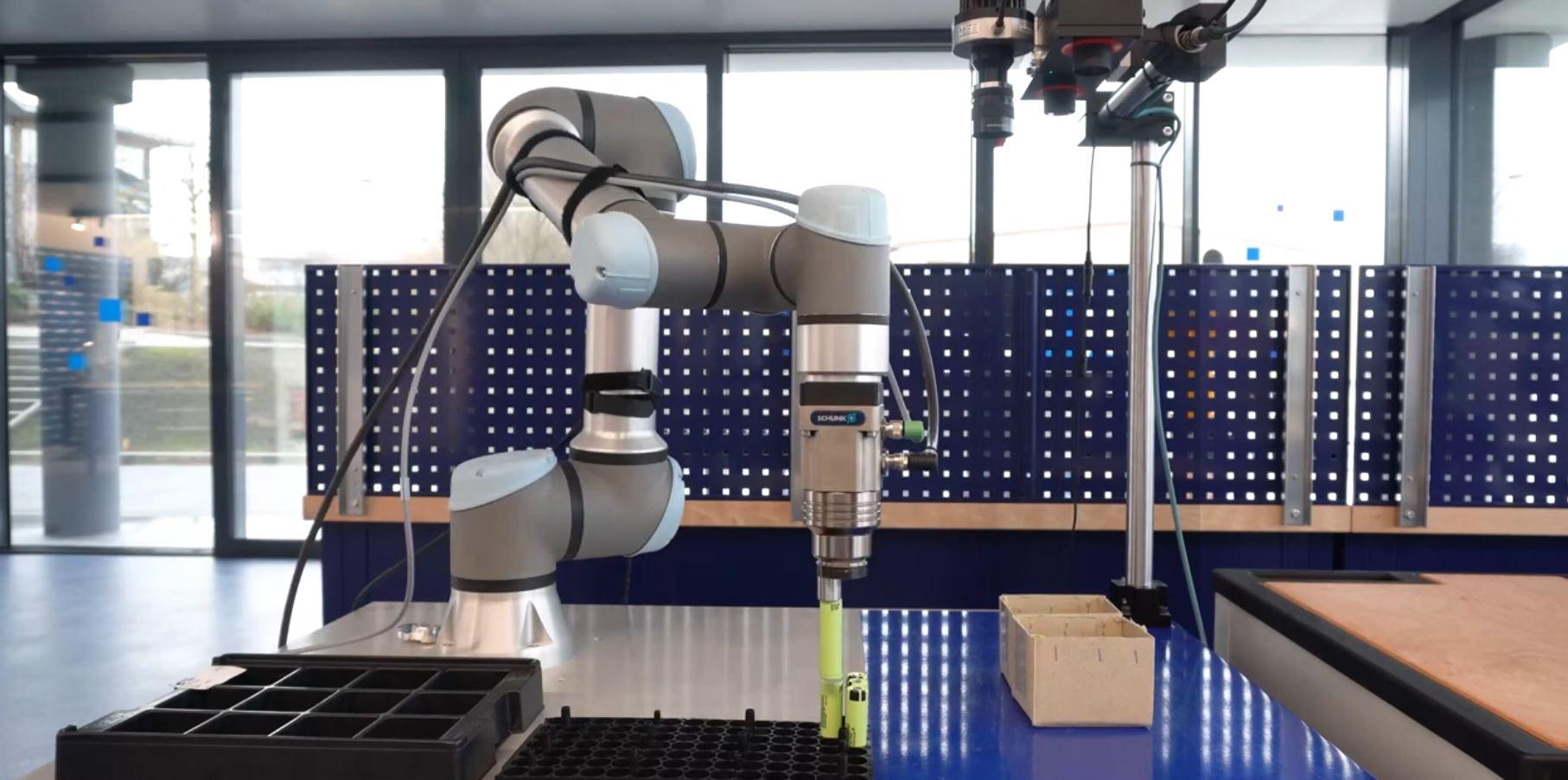

1 / 5Bin-picking with articulated arm robot and camera technology

Hardware Price:

ROI

6

months

set-up time

1

month

Max. payload

0.5

kg

Automated Separation of Ventilation Frames with igus robolink D

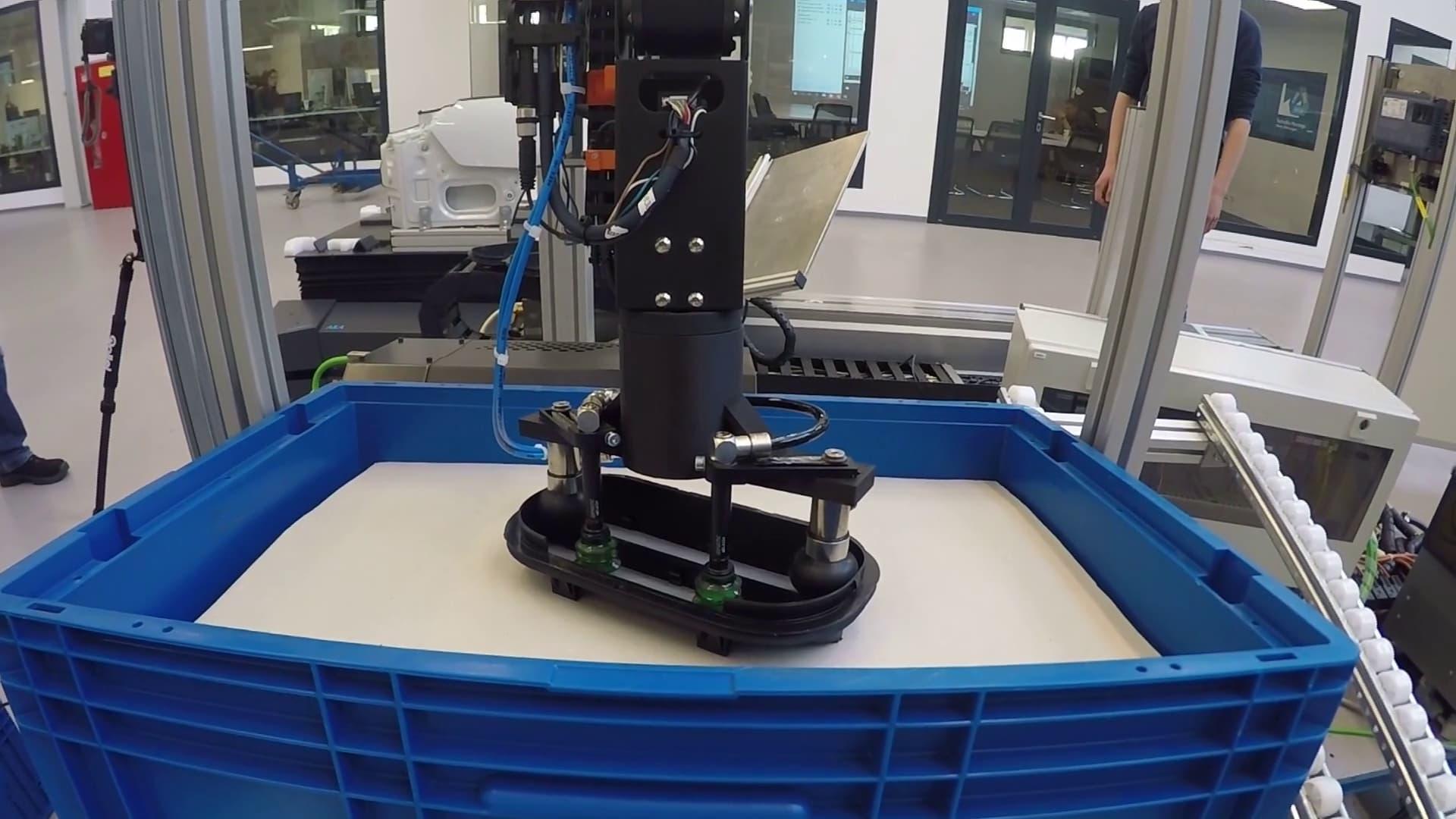

At the Volkswagen plant in Emden, numerous components must be removed from containers for further processing each day. In this project, the focus is on separating forced ventilation frames for the Passat and Arteon models.

What is the application?

The igus robolink D robot removes forced ventilation frames from small load carriers (KLT) and disposes of cardboard intermediate layers. The parts are then passed on to a 6-axis robot for inline assembly.

What are the advantages of the solution?

The automated system ensures stable material flow and relieves workers from repetitive handling tasks. Integration into the line process increases production efficiency and reliability.

What are the advantages of the robot?

The lightweight robolink D features modular design, camera-assisted precision, and a 3D-printed gripper, making it ideal for space-saving, flexible part separation.

Smart Automation for Streamlined Assembly

By combining lightweight robotics with intelligent control, this solution reduces manual effort while increasing consistency in automotive part handling.

2 Components