1 / 3

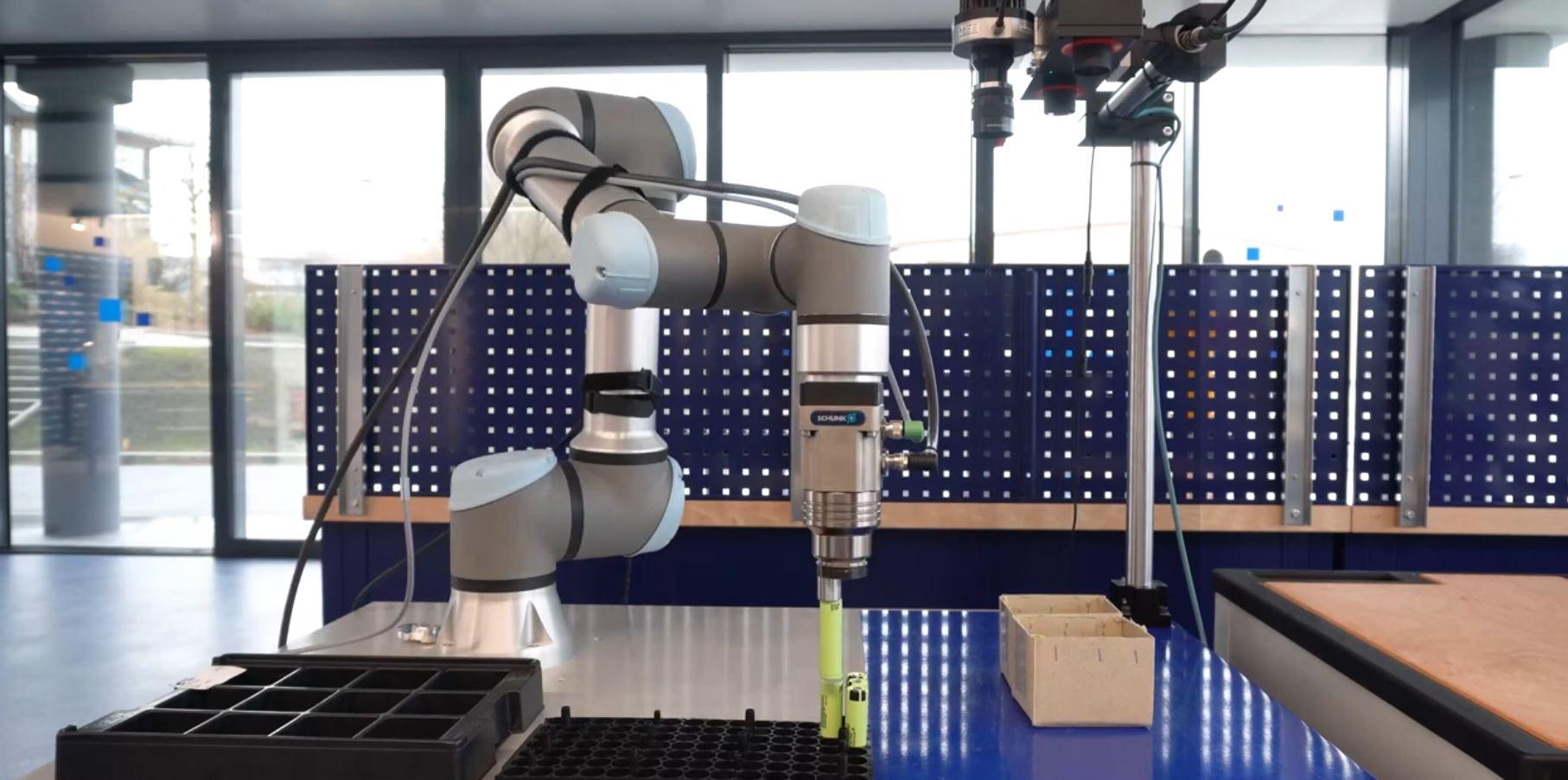

1 / 3Robotik in der Landwirtschaft: vertical Farming mit Robotern

Smart farming towers built for any environment, anywhere in the world

Hardwarepreis:

DOF

3

Maximale Nutzlast

5

kg

Maximale Geschwindigkeit

0,5

Meter pro Sekunde

Smart Indoor Farming mit präzisen Portalsystemen von igus®

Intelligent Growth Solutions (IGS) revolutioniert die vertikale Landwirtschaft mit einem modularen Indoor-Farming-System. Es ermöglicht Landwirten die volle Kontrolle über Klima, Licht und Nährstoffe – unabhängig von Standort und Wetter. Eine zuverlässige Automatisierung bildet dabei das Rückgrat des wirtschaftlichen Betriebs.

Was ist die Anwendung?

Die IGS-Türme steuern Licht, Temperatur, Luftfeuchtigkeit und CO₂ für jede Pflanzenebene präzise. Ziel ist der ertragreiche Anbau verschiedenster Kulturen auf minimaler Fläche – ganzjährig und automatisiert.

Welche Vorteile bietet die Lösung?

Skalierbarkeit: Einsetzbar weltweit

Präzision: Mikroklimakontrolle pro Träger

Nachhaltigkeit: Geringer Ressourcenverbrauch

Welche Vorteile bietet der Roboter?

Das drylin®-Portalsystem von igus® überzeugt durch:

Wartungsfreiheit: Keine Schmierung nötig

Langlebigkeit: Kein Verschleiß nach 1 Jahr Betrieb

Effizienz: Leiser, reibungsarmer Ablauf

Zukunftsfähige Landwirtschaft neu gedacht

IGS kombiniert Hightech mit Nachhaltigkeit – für sichere, automatisierte Lebensmittelproduktion an jedem Ort der Welt.

2 Komponenten