1 / 5

1 / 5Automatisch sortieren für den Brandschutz

Hardwarepreis:

Projektkosten

15.000

EUR

ROI

12

Monate

Pick-Rate

30

Picks pro Minute

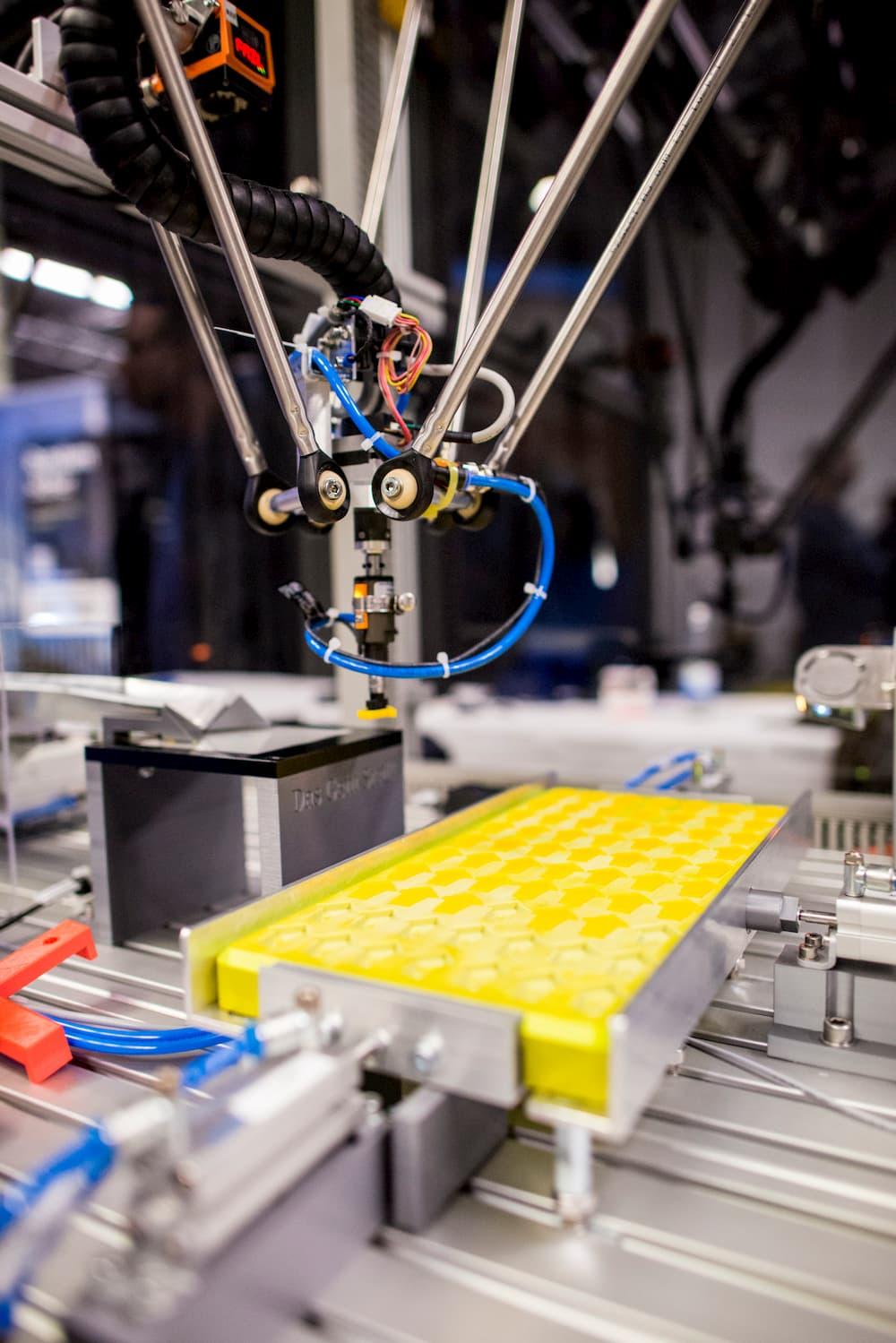

Effizientes Sortieren mit Delta-Roboter: Automatisierung in der Glasproduktion

Die Vetrotech Saint-Gobain Kinon GmbH, ein weltweiter Marktführer in der Produktion von Sicherheits- und Hightech-Glas, hat ihren Workflow für die Herstellung von feuerfestem Glas optimiert. Bisher war die Platzierung von Plastikkomponenten in Formen als Platzhalter auf manuelle Arbeit angewiesen. Um die Effizienz zu steigern und die Belastung der Mitarbeitenden zu reduzieren, hat das Unternehmen einen igus Delta-Roboter mit Saugnapf implementiert, der eine maximale Pick-Rate von 30 Picks/Minute erreicht und Schüttgut auf vorgegebenen Paletten sortiert.

Was ist die Anwendung?

Der Delta-Roboter automatisiert das Sortieren und Platzieren von Plastik-Platzhaltern in Formen, wodurch manuelle, repetitive Aufgaben im Produktionsablauf überflüssig werden.

Welche Vorteile bietet die Lösung?

Entlastung der Mitarbeitenden: Verringert die Belastung durch monotone Arbeit und ermöglicht den Einsatz von Mitarbeitenden für komplexere Aufgaben.

Kosteneffizienz: Amortisiert sich innerhalb von 12 Monaten durch die reduzierte Abhängigkeit von Arbeitskräften.

Steigerung der Produktionsgeschwindigkeit: Beschleunigt Sortierprozesse und sorgt gleichzeitig für zuverlässige Ergebnisse.

Welche Vorteile bietet der Roboter?

Der igus Delta-Roboter bietet eine leistungsstarke Lösung für die Glasproduktion:

Hohe Präzision: Die Saugnapftechnologie ermöglicht eine sichere und genaue Platzierung.

Schneller Betrieb: Verarbeitet bis zu 30 Picks/Minute und optimiert den Workflow.

Wartungsarm: Robustes Design erfordert lediglich minimalen Wartungsaufwand.

Optimierung der Glasproduktion durch automatisiertes Sortieren

Die Integration des igus Delta-Roboters hat die Sortieraufgaben bei Vetrotech Saint-Gobain Kinon GmbH revolutioniert, die Arbeitsqualität verbessert und die Produktionsgeschwindigkeit gesteigert. Durch die Automatisierung repetitiver Prozesse verbessert das Unternehmen die Effizienz, senkt Kosten und ermöglicht den Mitarbeitenden, sich auf wertschöpfende Tätigkeiten zu konzentrieren – eine ideale Lösung für moderne Glasherstellungsprozesse.

2 Komponenten